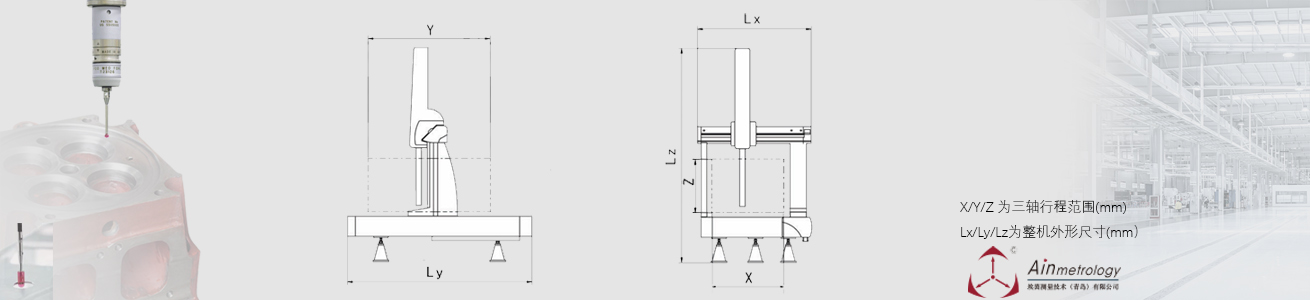

| BMS | 行程范围 | 外形尺寸 | ||||

| STD | X | Y | Z | Lx | Ly | Lz |

| 05.07.05 | 500 | 700 | 500 | 1030 | 1530 | 2480 |

| 06.08.06 | 600 | 800 | 600 | 1130 | 1630 | 2680 |

1.因网站改版,表格参数仅标注该系列三坐标测量机行程范围及外形尺寸;

2.具体测量精度,根据整机配置会略有出入,测量机的整体重量及承重,请及时与我们的销售/技术支持落实;

3.由于产品技术更新,造成描述/参数等不一致情况;具体以双方合同及技术协议约定为准;本站不代表最新结果。

主体框架:

优质天然花岗岩工作台,配置M8螺纹镶嵌件。

三轴导轨优质天然花岗岩,具有相同的温度特性和抗实效变形能力。

X向三角梁结构,降低运动负荷、提高整机性能,是目前保证稳定性和刚性的最佳结构设计。

Y轴整体下燕尾型导轨,有效减少运动扭摆,最大限度保证测量机精度和重复性。

优质天然花岗岩工作台,配置M8螺纹镶嵌件。

三轴导轨优质天然花岗岩,具有相同的温度特性和抗实效变形能力。

X向三角梁结构,降低运动负荷、提高整机性能,是目前保证稳定性和刚性的最佳结构设计。

Y轴整体下燕尾型导轨,有效减少运动扭摆,最大限度保证测量机精度和重复性。

计数系统:

RENISHAW RGS20 系列金属带式光栅尺

RENISHAW RGH22 系列读数头,分辨率0.5μm

气动部分:

预载荷气浮轴承环抱高精度自洁式气浮轴承分布,优化气浮间隙,提高稳定性。

三轴具有独立的气动系统,可独立调节气压及流量,达到最佳的运动状态。

Z向采用德国FESTO可调气动平衡,运动平稳并可在紧急情况下自动制动,保证安全。

日本SMC 空气过滤系统

发货包装:

优化的主机紧固包装,主体与外罩独立包装,无干涉及磨损。

随机资料:产品合格证,装箱单

国内:防震木箱包装;陆运

出口:免熏蒸包装箱;海运

BMS系列手动可升级型三坐标测量机,手动操作方式,升级前无伺服驱动部分,该系列升级为对应自动型/全自动型/五轴等测量机后,控制系统参照升级后相应机型配置。

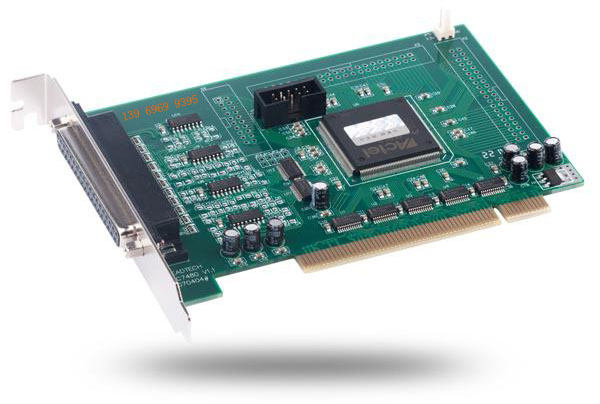

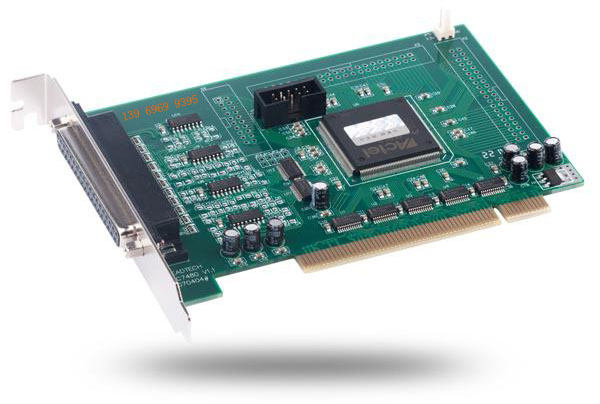

BMS手动可升级机型标配采用ENC7480控制卡进行数据采集,并与测量软件通信。

ENC7480产品特点:

-采用专用芯片设计,运行速度快、可靠性高。

-信号接口丰富,可以采集4轴正交编码器信号,计数器为28位,采样频率为4MHz.

-具有外部信号触发后硬件自动锁存位置的功能。

-I/O接口可提供了32路通用数字输入和32路通用数字输出。

BMS手动可升级机型标配采用ENC7480控制卡进行数据采集,并与测量软件通信。

ENC7480产品特点:

-采用专用芯片设计,运行速度快、可靠性高。

-信号接口丰富,可以采集4轴正交编码器信号,计数器为28位,采样频率为4MHz.

-具有外部信号触发后硬件自动锁存位置的功能。

-I/O接口可提供了32路通用数字输入和32路通用数字输出。

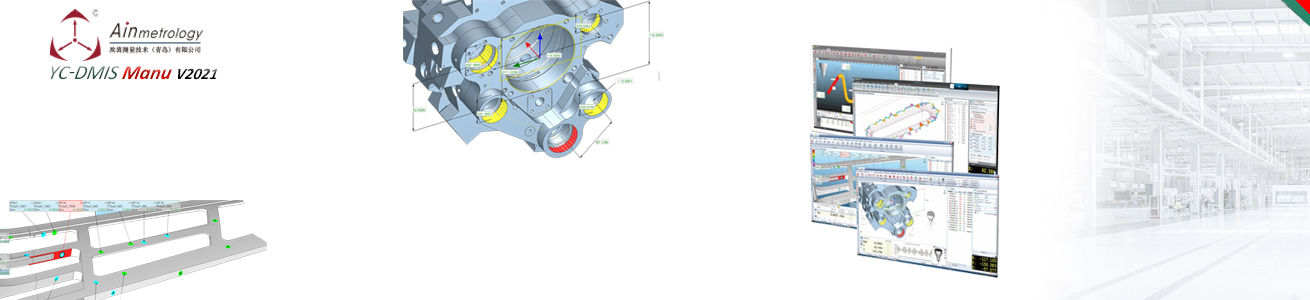

标配软件:YC-DMIS Manu

Axel 7 定制软件正不断融入YC-DMIS 元素,软件几何算法通过权威PTB和NPL认证;

Windows系统图形操作界面,如office一样轻松上手,使测量工作变得更快更轻松更省力!并可根据用户需求增加不同的功能模块。

全新睿伴界面,集成并大幅增强之前Axel版本中广受欢迎的工具栏,极大提高了日常工作效率,为您带来更多生产效益,在同一个用户界面内就能完成几何测量工作!

- 同一测量窗口中可显示多个坐标系以及丰富的图形化拟合选项

- 工件测量窗口多视图表示,图形化视图缩放、旋转可选3D实体及线框显示

- 全尺寸测量和几何公差

- 丰富的图形化编辑功能库。

- 全新结果敏感的智能构造功能

- 用户自定义公式计算结果

- -鼠标旋转/平移和缩放/视图网格线/可调节光影

- 支持手动测量序列的“Go模式”

- 大幅增强特征测量功能的Go模式自动视角回放

- 支持DMIS/文本程序导入/导出。

- 支持XYZ/YBC坐标数据输入以及XYZ到YBC转换。

- DDE/文件/串行口数据导出至SPC和Excel电子表格

- 测量结果可导出为微软Excel电子表格和HTML格式并多种预定义模板可供选择

- 全功能图形化测量报告生成器,并支持用户自定义。

- 几何元素测量:点、圆、直线、弧、平面、键槽、球、圆柱、圆锥、曲线、曲面。

- 几何元素构造:投影、中分、相交、相切、镜像、拟合、平移、垂直、平行、组合、旋转、偏置。

- 形位公差评价:直线度、平面度、圆度、圆柱度、 圆锥度、球度、距离、夹角、垂直度、平行度、倾斜度、位置度、对称度、同轴度、同心度、跳动。

II. 配套计算机Computer System

- 实际发货不低于以下配置:

- 戴尔计算机 DELL Computer

- 酷睿i3处理器;主频≥3.2GHz;4G内存;2G独显;

- 1TB 硬盘;DVD光驱;21寸液晶显示器

- Core I3 @3.2GHz;4GDDR RAM;2G VGA,1TB SATA

- DVD ROM,21” LCD

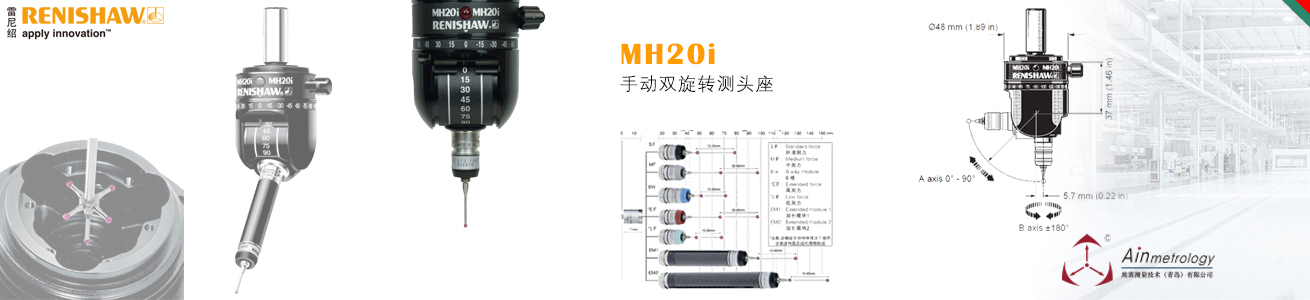

I. RENISHAW MH20i 测头座

MH20i具有良好的分度定位重复性,从而有效地提高了多方向测量的效率,该测座具有168个可重复定位的空间位置,可实现A轴和B轴以15度为增量移动,只需对每一测针位置进行一次标定即可,无需重新定位。确保了快速零件检测能力。

MH20i has a good degree of positioning repeatability, thereby effectively improving the efficiency of multi-direction measurement .The probe can be moved to 168 repeatable positions of the spatial location in 15-degree increments using both the A and B axes, requiring a one-time only qualification for each stylus position; ensuring rapid parts detection capabilities.

II. RENISHAW TP20 标准测力模块

集成的TP20 模块是一种可5方向或6方向操作的触发式测头。

可以手动或自动改变测针的配置而不需要重新定位测针,在检测时可节省很多时间。

The integral TP20 touch-trigger probe gives 5-axis or 6-axis operation.

It can rapid auto Exchange between stylus configuration or by hands without the need to re-calibrate and save much time.

III. RENISHAW 测针组

| 直测针/各一支 | |||

| 品名 | 直径 | 长度 | RENISHAW |

| PS9R | Φ1 | 10 | A-5000-7806 |

| PS23R | Φ1 | 20 | A-5000-7808 |

| PS8R | Φ2 | 10 | A-5000-7807 |

| PS2R | Φ2 | 20 | A-5000-3603 |

| PS1R | Φ3 | 10 | A-5000-3604 |

| PS16R | Φ3 | 20 | A-5000-4160 |

| PS12R | Φ4 | 10 | A-5000-4154 |

| PS17R | Φ4 | 20 | A-5000-4161 |

| 测针加长杆/各一支 | |||

| SE4 | - | 10 | A-5004-7585 |

| SE5 | - | 20 | A-5004-7586 |

| SE6 | - | 30 | A-5004-7591 |

| 五方向转接座 | |||

| SC2 | - | - | A-5000-3627 |

| 加长模块/选加 | |||

| EM1 | - | 71 | A-1371-0430 |

| EM2 | - | 96 | A-1371-0431 |

| 供货数以合同为准;长度单位:mm | |||

RENISHAW 英国进口标准Φ19标准球;

或国产Φ15/25标准球,具体以合同约定为准。

A.包装运输 Packing Freighting and Delivery

防震木箱包装,包装、运输由供货方负责,在用户现场用户应予以协助;包装、运输费由供货方负担。

We use quakeproof wooden case package. Packing and freighting will be carried out and paid by the supplier. At the user’s site, the user should provide support and help.

B.安装调试 Installation and Debugging

1.测量机所需的气源、电源、温度环境甲方根据乙方要求自行解决,费用甲方承担。

The supply of gas, electricity and temperature condition required by the CMM shall be settled by Party A in accordance of Party B’s requirements. Party A should pay for this.

2.乙方在合同生效时提供地基等设施条件文件,甲方根据乙方提供的地基、接地装置图纸,在发货前完成基础工程和机房配套电气设施。甲方收到货并具备安装条件后,提前7天通知乙方安排技术人员前往安装调试。乙方负责测量机就位和安装技术指导,进行测量机联机和精度调试。为使安装调试工作顺利进行, 甲方应在人员,时间和吊装运输设备方面给予合作,直至测量机验收交付。

Party B shall provide documents of facilities such as the found-base. Party A shall finish the foundation project and the electricity and gas facilities in machine room according to the found base and earthing drawings provided by Party B. After Party A receives the machine and has the condition of installation, it shall inform Party B 7 days in advance to send technicians to install and adjust the machines. Party B takes charge in the presence of the measurement machine, the technical guidance of installation, the connection of the machines and the precision debug. In order to carry out the work smoothly, Party A shall cooperate in terms of staff, time and hoisting transporters.

C.人员培训 Training

该课程旨在对测量机系统操作人员提供系统使用和坐标计量技术基本培训。

参加该课程培训的人员应选用有计量基础知识、计算机应用知识及有英语基础的人员。

The course is designed to train operators on the use of the system and on fundamentals of Coordinate Metrology. People attending this class are expected to have some familiarity with metrology knowledge, PC application skill and English.

培训时间: 1-3个工作日 Duration: 5 Days

培训地点: 青岛/客户现场 Place: Qingdao or at Customer factory

参加人数: 2-3人 Attendees: 2 Persons

D.保修服务 After-sell Services

测量机自验收之日起在正常使用情况下保修12个月,此期间由用户人为责任造成的硬件损坏进行维修时按成本收费;保修期满后负责长期有偿服务。进口件损坏由供货方与外商联系修理。

12 months guarantee free of charge after final acceptance, under regular service conditions. During this period, hardware damage caused by user’s personal mistake will be repaired only charging basis cost price. After that period, a long lasting pay service will be given. Supplier will connect with foreign merchant to solve the problem of import parts damage.

1. 用户在测量机发生故障时应及时详细告知故障情况。供货方接到通知后2小时做出反应。供货方有责任应用户要求在24小时内赶到用户现场负责处理。

When a fault happens to the CMM, a detailed fault condition should be provided by the user. Supplier will make reaction in 4 hours after receiving the trouble notice. Supplier has the duty of arriving to provide service at the user’s site in 24 hours.

2. 客户回访制度:在测量机投入使用后,公司工程师将不定期回访,以提供更多技术支持指导,使用户操作更加熟练,并正确对测量机做日常维护,延长测量机使用寿命。

Customer care system: after the measuring machine is put into use, the company engineer will not visit regularly to provide more technical support guidance, use the user's operation more skillfully, and make the daily maintenance of the measuring machine and prolong the service life of the measuring machine.

3. 在线远程支持制度:公司建立在线远程支持制度,可对客户终生免费提供技术支持,编程指导,使客户获得更便捷服务。

Online remote support system: the company establishes an online remote support system, which provides free technical support to customers for life, programming guidance, and enables customers to get more convenient services.

4. 供货方将以优惠价格向用户提供其它选加附件。

Supplier will provide user with other accessory options in a preferential price.

防震木箱包装,包装、运输由供货方负责,在用户现场用户应予以协助;包装、运输费由供货方负担。

We use quakeproof wooden case package. Packing and freighting will be carried out and paid by the supplier. At the user’s site, the user should provide support and help.

B.安装调试 Installation and Debugging

1.测量机所需的气源、电源、温度环境甲方根据乙方要求自行解决,费用甲方承担。

The supply of gas, electricity and temperature condition required by the CMM shall be settled by Party A in accordance of Party B’s requirements. Party A should pay for this.

2.乙方在合同生效时提供地基等设施条件文件,甲方根据乙方提供的地基、接地装置图纸,在发货前完成基础工程和机房配套电气设施。甲方收到货并具备安装条件后,提前7天通知乙方安排技术人员前往安装调试。乙方负责测量机就位和安装技术指导,进行测量机联机和精度调试。为使安装调试工作顺利进行, 甲方应在人员,时间和吊装运输设备方面给予合作,直至测量机验收交付。

Party B shall provide documents of facilities such as the found-base. Party A shall finish the foundation project and the electricity and gas facilities in machine room according to the found base and earthing drawings provided by Party B. After Party A receives the machine and has the condition of installation, it shall inform Party B 7 days in advance to send technicians to install and adjust the machines. Party B takes charge in the presence of the measurement machine, the technical guidance of installation, the connection of the machines and the precision debug. In order to carry out the work smoothly, Party A shall cooperate in terms of staff, time and hoisting transporters.

C.人员培训 Training

该课程旨在对测量机系统操作人员提供系统使用和坐标计量技术基本培训。

参加该课程培训的人员应选用有计量基础知识、计算机应用知识及有英语基础的人员。

The course is designed to train operators on the use of the system and on fundamentals of Coordinate Metrology. People attending this class are expected to have some familiarity with metrology knowledge, PC application skill and English.

培训时间: 1-3个工作日 Duration: 5 Days

培训地点: 青岛/客户现场 Place: Qingdao or at Customer factory

参加人数: 2-3人 Attendees: 2 Persons

D.保修服务 After-sell Services

测量机自验收之日起在正常使用情况下保修12个月,此期间由用户人为责任造成的硬件损坏进行维修时按成本收费;保修期满后负责长期有偿服务。进口件损坏由供货方与外商联系修理。

12 months guarantee free of charge after final acceptance, under regular service conditions. During this period, hardware damage caused by user’s personal mistake will be repaired only charging basis cost price. After that period, a long lasting pay service will be given. Supplier will connect with foreign merchant to solve the problem of import parts damage.

1. 用户在测量机发生故障时应及时详细告知故障情况。供货方接到通知后2小时做出反应。供货方有责任应用户要求在24小时内赶到用户现场负责处理。

When a fault happens to the CMM, a detailed fault condition should be provided by the user. Supplier will make reaction in 4 hours after receiving the trouble notice. Supplier has the duty of arriving to provide service at the user’s site in 24 hours.

2. 客户回访制度:在测量机投入使用后,公司工程师将不定期回访,以提供更多技术支持指导,使用户操作更加熟练,并正确对测量机做日常维护,延长测量机使用寿命。

Customer care system: after the measuring machine is put into use, the company engineer will not visit regularly to provide more technical support guidance, use the user's operation more skillfully, and make the daily maintenance of the measuring machine and prolong the service life of the measuring machine.

3. 在线远程支持制度:公司建立在线远程支持制度,可对客户终生免费提供技术支持,编程指导,使客户获得更便捷服务。

Online remote support system: the company establishes an online remote support system, which provides free technical support to customers for life, programming guidance, and enables customers to get more convenient services.

4. 供货方将以优惠价格向用户提供其它选加附件。

Supplier will provide user with other accessory options in a preferential price.

选配附件 Option

I.冷干机 Refrigeration Dryer

三坐标用气源的初级空气过滤,除水,除油,为三坐标本身所配置的精密过滤系统减轻压力,有效延长测量机的使用寿命(价格另议)。

The refrigeration dryer can be used for Primary air filtration system. Water/oil removal; Reduce stress the sophisticated filtering system, and effectively extending the life of the measuring machine.

II.UPS稳压电源 Power Supply

提供电压及断电延迟保护,防止客户现场因为电压不稳定造成测量机元器件的损坏及防止因意外断电造成正在测量过程中的数据丢失(价格另议)。

The CMM component may be damaged caused by voltage instability at the customer site,and the unexpected power outages makes the measurement data loss. So, you may need a voltage protection and power-off delay to avoid the possible damage.

III.延保服务Extend Warranty

用户可根据自身需要对质保期进行延保服务,延长质保期为3年/5年,具体以合同约定为准。

用户可一次性签订多年的校验服务协议,具体优惠可咨询在线客服。

Ⅳ.复合式测头

用户可根据需要增加激光/影像测头系统,实现一机多用。

手动型测量机只支持增加影像复合式测头,自动机可在原RENISHAW测头的基础上单独或同时增加激光扫描/影像测头系统。

I.冷干机 Refrigeration Dryer

三坐标用气源的初级空气过滤,除水,除油,为三坐标本身所配置的精密过滤系统减轻压力,有效延长测量机的使用寿命(价格另议)。

The refrigeration dryer can be used for Primary air filtration system. Water/oil removal; Reduce stress the sophisticated filtering system, and effectively extending the life of the measuring machine.

II.UPS稳压电源 Power Supply

提供电压及断电延迟保护,防止客户现场因为电压不稳定造成测量机元器件的损坏及防止因意外断电造成正在测量过程中的数据丢失(价格另议)。

The CMM component may be damaged caused by voltage instability at the customer site,and the unexpected power outages makes the measurement data loss. So, you may need a voltage protection and power-off delay to avoid the possible damage.

III.延保服务Extend Warranty

用户可根据自身需要对质保期进行延保服务,延长质保期为3年/5年,具体以合同约定为准。

用户可一次性签订多年的校验服务协议,具体优惠可咨询在线客服。

Ⅳ.复合式测头

用户可根据需要增加激光/影像测头系统,实现一机多用。

手动型测量机只支持增加影像复合式测头,自动机可在原RENISHAW测头的基础上单独或同时增加激光扫描/影像测头系统。

推荐产品